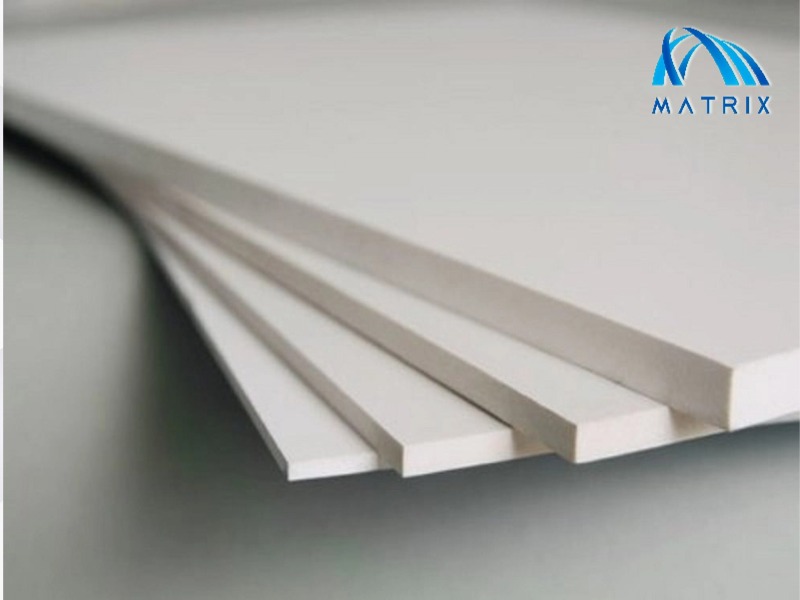

Forms: Sheet / Plates / Pad / Thin Slab / Rod

Product Origin: China

Color: Black / White

HS Code: 391890、391690

PVC (polyvinyl chloride sheet) has strong corrosion resistance. It is easy to process. Cutting, welding and bending are all extremely simple. High strength, high rigidity and high hardness; Good electrical insulation; Good chemical stability; Self-extinguishing; Low water absorption Easy to bond and easy to paint.

CPVC board is a kind of hard thermoplastic. While retaining the similar properties of PVC board, it has better high-temperature resistance. Compared with common PVC, CPVC boards have better heat resistance and corrosion resistance. CPVC boards have excellent insulation, thermoplasticity, chemical stability, corrosion resistance and water resistance, and are widely used in chemical treatment plants. The bending, forming and welding properties of CPVC boards make them widely used in various fields, including containers, scrubbers and ventilation systems.

Product specifications: Thickness 2-50mm × Width 1000, 1300, 1500, 2000mm × length 1000, 2000mm

Colors: Gray series (dark gray, light gray, grayish white), white series (white, porcelain white, cream white), colored series (red, blue, yellow, orange red, ivory white, yellowish white, etc.)

2. Tensile strength: Transverse/longitudinal ≥52.0Mpa;

3. The softening point of the microcard is ≥70℃. Melting point: 120℃

4. Flame retardant coefficient: UL-94 vertical burning standard V0 grade;

5. Rockwell hardness: 82 degrees

6. Temperature resistance: The continuous temperature resistance does not exceed 50℃, and the instantaneous temperature resistance does not exceed 60℃.

2. Industrial containers: casing troughs, water tanks, vertical/horizontal storage tanks for chemical industry, etc.

3. PCB equipment: etching machines, volcanic ash grinding machines, demolding and drying machines, etc.

4. Automated equipment: silicon wafer cleaning machines, electronic glass cleaning machines, electroplating equipment, etc.

5. Coating equipment: Electrostatic powder coating rooms, powder coating equipment components, etc.

6. Laboratory equipment: medicine cabinets, salt spray testing machines, constant temperature detection machines, etc.

7. Ventilation equipment: Centrifugal fans, ventilation ducts, acid mist waste gas towers, waste gas treatment equipment, etc.

8. Printing industry: Advertising silk-screen printing, warning signs and other sign backboards, etc.

9. Other industries: Cable covers, non-fired brick support plates, mold manufacturing, pad plates.

2. Reliable insulation performance, fire-resistant and flame-retardant;

3. Resistant to acid and alkali, and resistant to chemical corrosion;

4. Extremely easy to process and has excellent welding performance;

5. Operating temperature: -15℃ to 60℃

2. Processing methods: hot melt welding, hot bending forming, cold bending forming, vacuum forming, drilling, punching, engraving, PVC glue bonding, etc. Vacuum forming is suitable for thin PVC sheets of 2mm or less. Hot bending, cold bending forming and punching processing are suitable for plates with low density and high toughness.